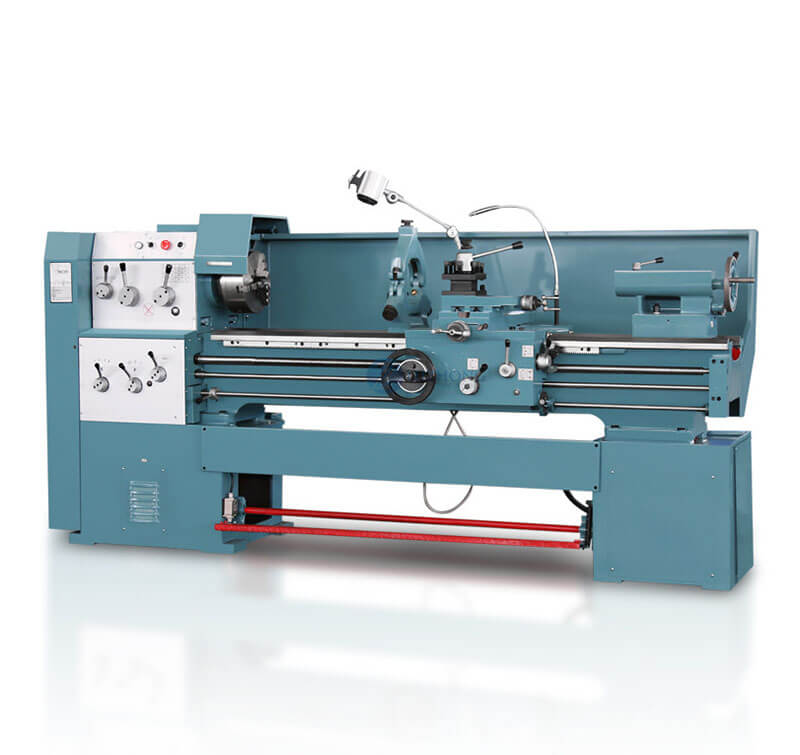

Horizontal Lathe Machines description:

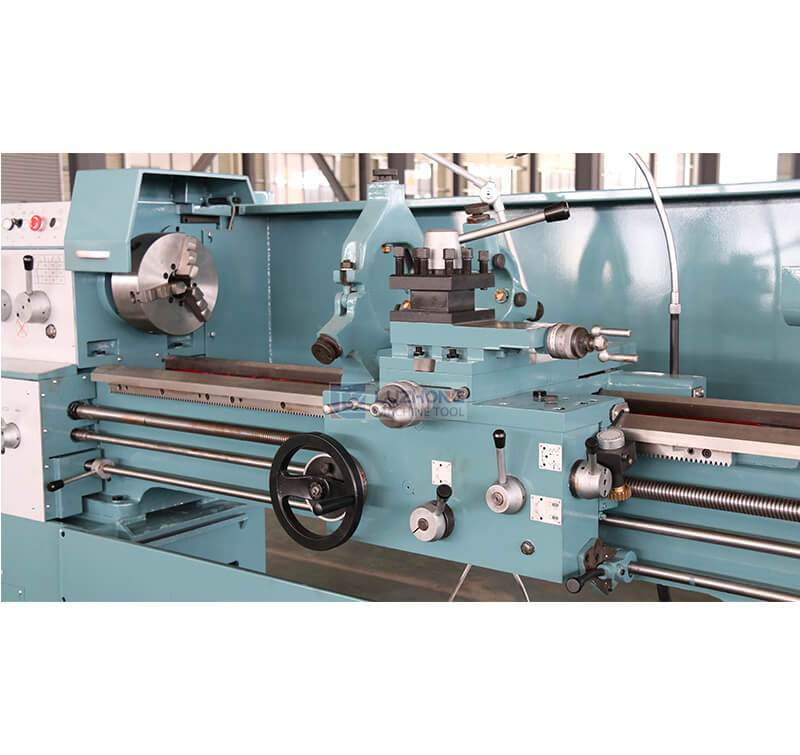

1.Bed rail by super audio quenching and grinding.

2.Precision grinding of the main shaft box, low noise.

3.More thread type.

4.Electrical safety performance is good, high reliability.

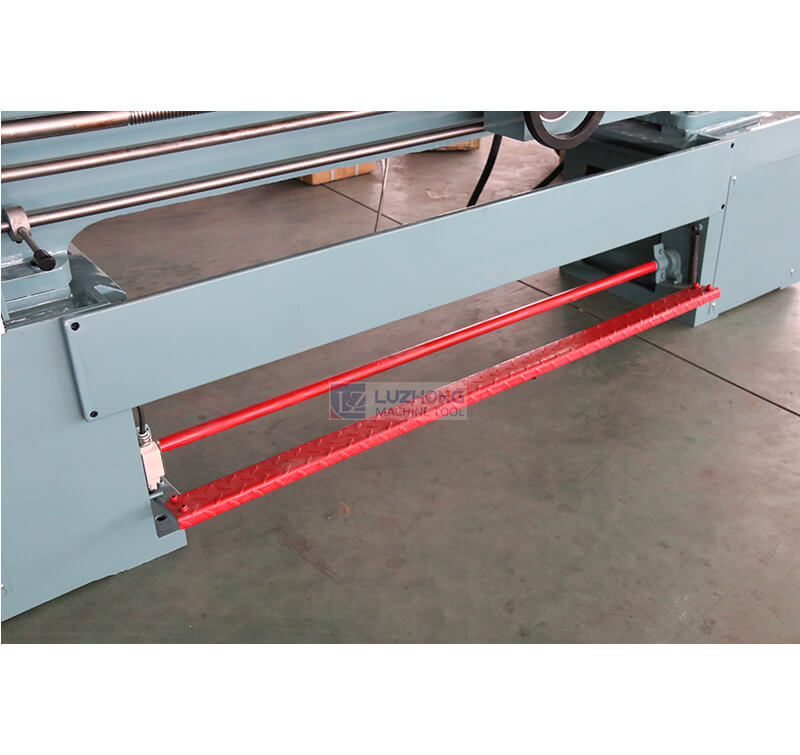

5.With electromagnetic brake, the color of available options.

Horizontal Lathe Machines Technical Specifications:

Specifications | C6136 | |

Capacity | Max.Swing over bed | 360mm |

Max. rotating diameter | 200mm | |

Center distance | 750、1000、1500、2000mm | |

Spindle hole | 52mm | |

Spindle | Nose | ISO-C6 |

Tap | MT6 | |

Speeds(Number) | 36-1400rpm (12 Steps) | |

Feed | Metric threads range(Kinds) | 0.5-14mm (18 Kinds) |

Inch threads range(Kinds) | 2-40/inch (28 Kinds) | |

Moudle threads range(Kinds) | 0.25-3.5mπ (17 Kinds) | |

Compound rest travel | 150mm | |

Cross slide travel | 180mm | |

Cross-section size of toolshank | 20×20mm2 | |

Tailstock | Dia.of sleeve | 75mm |

Taper of sleeve | MT5 | |

Travel of sleeve | 160mm | |

Main motor power | 4/5.5KW | |

Machines size (L*W*H mm) | Overall dimensions for750mm | 2100×1150×1550mm |

Overall dimensions for1000mm | 2350×1150×1550mm | |

Overall dimensions for1500mm | 2850×1150×1550mm | |

Overall dimensions for2000mm | 3350×1150×1550mm | |

Weight(kg) | Weight for 750mm | 1500kg |

Weight for 1000mm | 1600kg | |

Weight for 1500mm | 1800kg | |

Weight for 2000mm | 2000kg | |

In order to ensure the quality of the Lathe Machines, you can consider the following suggestions:

First, consider the processing sequence of the parts:

1. Drill first and then flat end (this is to prevent shrinkage during drilling);

2. Rough turning first, then finishing turning (this is to ensure the accuracy of parts);

3. The first processing tolerance is large and the last processing tolerance is small (this is to ensure that the small tolerance size surface is not scratched and to prevent parts from being deformed).

According to the hardness of the material, choose a reasonable speed, feed rate and cutting depth:

1. The carbon steel material chooses high speed, high feed and large cutting depth. For example: 1Gr11, select S1600, F0.2, and cut depth 2mm;

2. The hard alloy chooses low speed, low feed and small cutting depth. For example: GH4033, select S800, F0.08, cut depth 0.5mm;

3. Titanium alloy chooses low speed, high feed and small cutting depth. For example: Ti6, select S400, F0.2, and cut depth 0.3mm. Take the processing of a part as an example: the material is K414, this material is a very hard material. After several tests, the final selection is S360, F0.1, and the cutting depth of 0.2 before processing qualified parts.

Analysis of Wear in CNC Horizontal Lathe Machines:

Wear on NC Face of CNC Lathe

Flank wear is frictional wear that occurs on the flank due to mechanical stress. Because the tool material is too soft, the rake angle of the tool is too small, the cutting speed is too high during the machining process, and the feed is too small, which causes excessive wear on the flank surface, which reduces the dimensional accuracy of the machining surface and increases the friction force. High abrasive tool materials, at the same time reduce the cutting speed, increase the feed, increase the rake angle of the tool, so as to avoid reducing the occurrence of flank wear.

CNC lathe tool edge wear

Boundary wear on the main cutting edge is common at the contact surface with the workpiece. One of the main reason is the friction caused by surface hardening and sawtooth cutting, which affects the flow of cutting and causes chipping. Only by reducing the cutting speed and feed speed, while selecting wear-resistant tool materials and increasing the rake angle, can the cutting edge be sharper.

Our service:

Our company formed a good win-win relationship with mechanical and electrical companies in provinces, complete sets of companies and foreign agents. Not only in the country Company formed a mature sales network not only in the country, but also our products are exported to South America, Africa, the Middle East, Southeast Asia and other countries, and are trusted and praised by vast number of users. Our factory focuses on strict and effective management, product quality and service is our eternal pursuit of the theme. Our company will always be the spirit of "the pursuit of excellence, sincere service" purposes, and strive to provide users with high-quality products and fast, thoughtful after-sales service.

We mainly produce various CNC lathe equipment, including vertical lathes and horizontal lathe equipment. If you need, welcome to contact us to know more information. We offer professional services, Simultaneously we guarantee product quality and delivery time.

More industry news and company information can be found in the news section.

FAQ

1、How can I choose the most suitable machines?

Please tell me your specifications ,I can choose the best model for you , or you can choose the exact model.You can also send us the products drawing ,we will choose the most suitable machines for you.Please tell me your specifications ,I can choose the best model for you , or you can choose the exact model.

You can also send us the products drawing ,we will choose the most suitable machines for you.

2、What's your main products of your company?

We specialized in all kinds of machines , such as lathe machine, cnc lathe machine, milling machine, cnc milling machine, vertical machining center, drilling machine, radial drilling machine, sawing machine, shaper machine and so on.

3、Where is our factory located? How can I visit there?

Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us.

4、What is your trade terms?

FOB, CFR and CIF all acceptable.

5、FOB, CFR and CIF all acceptable.

T/T ,30% initial payment when order ,70% balance payment before shipment; Irrevocable LC .

6、What's the MOQ?

1 set .(Only some low cost machines will be more than 1 set )

Copyright © Shandong Luzhong Machine Tool Co.,Ltd. All Rights Reserved