The main performance characteristics:

1 Machine tool head box and bed, tailstock, Supporting plate, etc. the combination of surface between manual scraping, machine to undergo a rigorous inspection, effectively ensure the machine tool accuracy and stability.

2 Machine adopts high strength cast iron, copper and chromium special materials are added, the bed width 400mm, bed rail quenching depth up to 4mm, effectively improves the abradability and stability of the machine.

3 The machine tool bed head box lubrication uses the pump to carry on the circulation forced lubrication, in view of the south hot weather, has guaranteed the bed head box cleanliness and the heat radiation characteristic, has effectively extended the bearing and gear's service life.

4 Wafangdian Bearing is used in machine tool spindle, the spindle through hole diameter 80mm, machine tool gear with precision grinding, can effectively improve the hardness of the gears, to reduce noise of the machine.

5 Machine tool uses the domestic brand lead screw, the silk mother uses the high quality bronze alloy to guarantee the wear-resisting property and the precision maintenance.

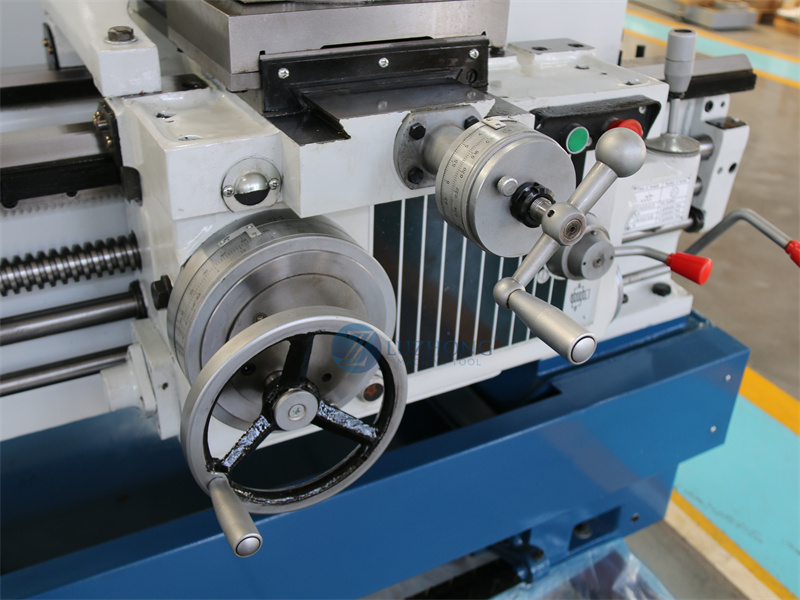

6 The machine adopts high strength four station turret shank size: 25x25mm.

Application:

1 CA series ordinary horizontal lathe is used to turning internal and external cylindrical surface, conical surface, and other rotating surface, turning various metric and inch, modulus and pitch thread, and the pitch diameter of the thread and pull the drilling and oil tank etc., is general very strong horizontal lathe, Widely applicable batch processing of various shaft and disc parts.

2 The series lathe bed width in general lathe, 400mm rail width has higher stiffness, rail surface by intermediate frequency quenching, wear-resistant durable.

3 Handy machine operator concentration, slide plate is provided with a quick moving mechanism. Using single handle operation, humanization.

4 The rigidity of the machine tool structure and the transmission stiffness are higher than the general lathe, the power utilization rate is high, which is suitable for the strong cutting.

5 Before leaving the machine tool factory, the machine tool is tested strictly according to the inspection procedure, and the machine tool is tested to ensure that the machine tool has good stability and reliability.

Product main technical parameters:

SPECIFICATIONS | Units | CA6140 | CA6240 |

Swing over bed | mm | 400 | |

Swing over cross slide | mm | 210 | |

Swing over gap | mm | - | 630 |

Gap length | mm | - | 210 |

Distance between centers | mm | 750/1000/1500/2000/2200/3000/4000 | |

Spindle bore | mm | 52 B:80 C:105 | |

Spindle bore taper | - | MT6 B:90 1:20 C:113 1:20 | |

Spindle speed range | rpm | 10-1400/16-1400 | |

Spindle speed steps | - | 24 | |

Cross slide travel | mm | 320 | |

Top tool post travel | 140 | ||

Tool size | 25*25 | ||

Longitudinal feeds kinds | kinds | 64 | |

Longitudinal feeds range | mm/r | 0.028-6.33 | |

Cross feeds range kinds | kinds | 64 | |

Cross feeds range | mm/r | 0.014-3.16 | |

Longitudinal fast moving | m/min | 4 | |

Cross fast moving | m/min | 2 | |

Kinds of metric threads | kinds | 44 | |

Range of metric threads | mm | 1-192 | |

Kinds of inch threads | kinds | 21 | |

Range of inch threads | T.P.I. | 2-24 | |

Kinds of module threads | kinds | 39 | |

Range of module threads | M.P. | 0.25-48 | |

Kinds of diametral threads hreads | kinds | 37 | |

Range of diametral threads hreads | D.P. | 1-96 | |

Tailstock quill diameter | mm | 75 | |

Tailstock quill taper | - | MT5 | |

Tailstock quill travel | mm | 150 | |

Main motor power | kw | 7.5 | |

Coolant motor power | kw | 0.09 | |

Weight for 750 | kg | 2000 | |

Weight for 1000 | kg | 2100 | |

Weight for 1500 | kg | 2300 | |

Weight for 2000 | kg | 2600 | |

Weight for 3000 | kg | 3300 | |

Weight for 4000 | kg | 3800 | |

Dimension for 750 | mm | 2440*1150*1600 | |

Dimension for 1000 | mm | 2650*1150*1600 | |

Dimension for 1500 | mm | 3150*1150*1600 | |

Dimension for 2000 | mm | 3650*1150*1600 | |

Dimension for 3000 | mm | 4800*1150*1600 | |

Dimension for 4000 | mm | 5680*1150*1600 | |

Copyright © Shandong Luzhong Machine Tool Co.,Ltd. All Rights Reserved