The main performance characteristics:

1 Machine tool bed box, headstock and tailstock, pallet etc. the binding surface between the manual scraping machine, after rigorous testing, the precision and stability of the effective guarantee machine.

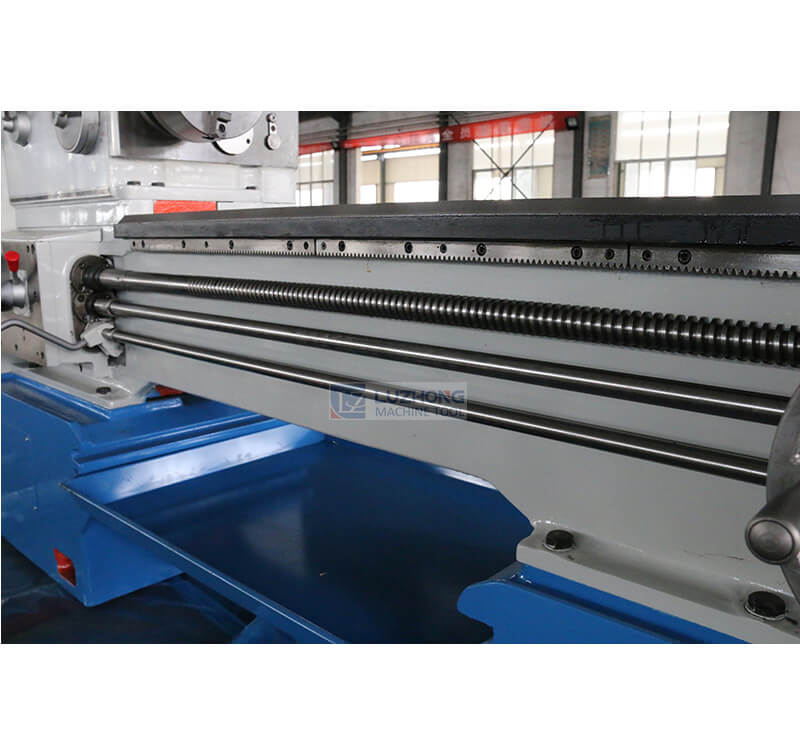

2 The machine adopts high strength cast iron, copper and chromium added special materials, bed width 400mm, bed rail quenching depth 4mm, effectively improve the wear resistance and stability of machine tool.

3 Machine tool bed box lubricated system by the use of the lubrication of the pump for lubrication, for the hot weather, to ensure the cleanliness of the bed box and heat dissipation characteristics, effectively extend the bearing and gear life.

4 Machine tool spindle using Wafangdian bearing, spindle hole diameter 52mm, the precision grinding machine tool gear, effectively improve the hardness, reduce machine noise.

5 Machine tool uses the domestic brand screw, wire mother uses the high quality bronze alloy to guarantee the wear resistance and the accuracy retention.

6 Machine tool with four position high strength tool, shank size: 25x25mm.

Application:

1 CA series of ordinary horizontal lathe is suitable for turning inside and outside cylindrical surface, conical surface and other rotating surface, turning various metric and inch, modulus and pitch thread, and can carry out the work of drilling and pulling oil groove, is a very versatile horizontal lathe, widely used in all kinds of shaft and disc parts of the batch processing.

2 This series of lathe bed width in general lathe, rail width 400mm has a high stiffness; guide rail surface is quenched by medium frequency, and is durable.

3 The machine operation is flexible and concentrated, the apron with fast moving mechanism. Using single handle vivid of the operation, pleasant and good.。

4 Machine tool structure rigidity and transmission rigidity are higher than the general lathe, the power utilization ratio is high, is suitable for the strong cutting.

5 Machine tool factory in strict accordance with the test procedures for testing, and make a strong cutting test, to ensure that the machine has a good accuracy and reliability.

Product main technical specifications:

Specifications | CA6161 CA6161B CA6161C | |

Max. Swing over bed | 610mm | |

Max. Swing over carriage | 370mm | |

Max. length of work piece | 750mm/1000mm/1500mm/2000mm/2200mm/3000mm/4000mm | |

Width of bed | 400mm | |

Section of turning tool | 25x25mm | |

Spindle | Spindle speeds | 10-1400rpm/16-1400rpm(24steps) |

Hole through spindle | 52mm. (80mm). [105mm] | |

Spindle taper | NO.6(MT6)(Φ90 1:20)[Φ113 1:20] | |

Feed | Number of feeds | 64 kinds(for each) |

Range of metric threads(kinds) | (1-192mm)44 kinds | |

Range of inch threads(kinds) | (2-24tpi)21 kinds | |

Range of module threads(kinds) | 0.25-48 (Moduie39kinds) | |

Range of pitch threads(kinds) | 1-96DP(37kinds) | |

Tailstock | Max. tail stock spindle travel | 150mm |

Tail stock spindle diameter | 75mm | |

Taper of tail stock spindle center hole | NO.5(MT5) | |

Main motor | 7.5KW(10HP) | |

Packing dimensions (L*W*Hmm) | Overall dimensions for750mm | 2550x1140x1750 |

Overall dimensions for1000mm | 2700x1140x1750 | |

Overall dimensions for1500mm | 3200x1140x1750 | |

Overall dimensions for2000mm | 3700x1140x1750 | |

Overall dimensions for2200mm | 4030x1140x1750 | |

Overall dimensions for3000mm | 4850x1140x1750 | |

Overall dimensions for4000mm | 5800x1140x1750 | |

Weight (kg) | Length | G.W N.W. |

Weight for 750mm | 2300 2180 | |

Weight for 1000mm | 2380 2250 | |

Weight for 1500mm | 2577 2437 | |

Weight for 2000mm | 2940 2787 | |

Weight for 2200mm | 3120 2970 | |

Weight for 3000mm | 3600 3450 | |

Weight for 4000mm | 3950 3800 | |

Copyright © Shandong Luzhong Machine Tool Co.,Ltd. All Rights Reserved