Main functions of cnc milling machine:

(1) Point control function: The point control of the CNC milling machine is mainly used for hole processing of workpieces, such as center drilling positioning, drilling, reaming, countersinking, reaming and boring.

(2) Continuous control function: Mill the plane and surface of the workpiece through linear interpolation, arc interpolation or complex curve interpolation movement of the CNC milling machine.

(3) Tool radius compensation function: If you directly program the workpiece contour line, the actual contour line will be increased by one tool radius value when processing the internal contour of the workpiece; when the external contour of the workpiece is processed, the actual contour line will be reduced by one tool radius value. Using the tool radius compensation method, the CNC system automatically calculates the tool center trajectory, deviates the tool center from the workpiece contour by a tool radius value, and processes a contour that meets the requirements of the drawing. Using the tool radius compensation function, changing the tool radius compensation amount can also compensate the tool wear amount and machining error, and realize the rough machining and finishing of the workpiece.

4) Tool length compensation function: Changing the compensation amount of the tool length can compensate the length deviation value after the tool is changed, and it can also change the plane position of the cutting process and control the axial positioning accuracy of the tool.

(5) Fixed cycle processing function: The application of fixed cycle processing instructions can simplify the processing program and reduce the programming workload.

(6) Subroutine function: If the workpiece is processed in the same or similar shape, it is written into a subroutine and called by the main program, which simplifies the program structure. The function of quoting subroutines makes the machining program modular. It is divided into several modules according to the procedures of the machining process, which are written into subroutines and called by the main program to complete the processing of the workpiece. This modular program is easy to debug and optimize the process.

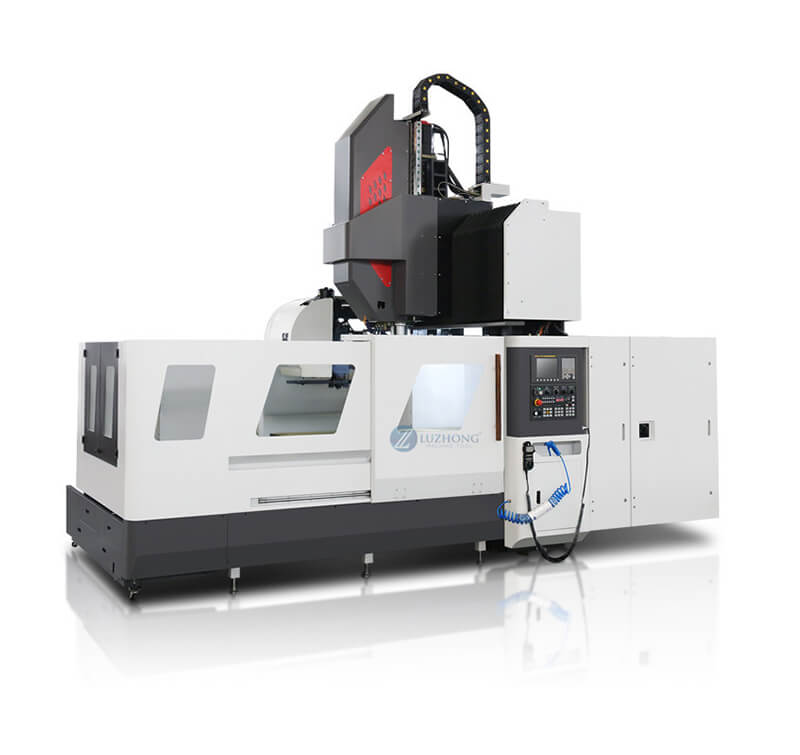

Cnc Gantry Milling Machine

Processing range of CNC gantry milling machine:

(1) Plane processing: The milling plane of CNC machine tools can be divided into the horizontal plane (XY) machining of the workpiece, the positive plane (XZ) machining of the workpiece and the side plane (YZ) machining of the workpiece. As long as the two-axis semi-controlled CNC milling machine is used to complete such a plane milling process.

(2) Surface processing: If milling complex surfaces, you need to use a CNC milling machine with three or more axes.

Equipment of CNC milling machine:

(1) Fixture: The universal fixture of CNC milling machine mainly includes flat-nose pliers, magnetic suction cup and platen device. For machining, large-volume or complex-shaped workpieces, a combined fixture must be designed. If pneumatic and hydraulic fixtures are used, the fixture can be controlled automatically through the program to achieve automatic assembly of the workpiece, which can further improve work efficiency and reduce labor intensity.

(2) Tools: Commonly used milling tools include end mills, end mills, forming mills and hole processing tools.

Copyright © Shandong Luzhong Machine Tool Co.,Ltd. All Rights Reserved