Product main features:

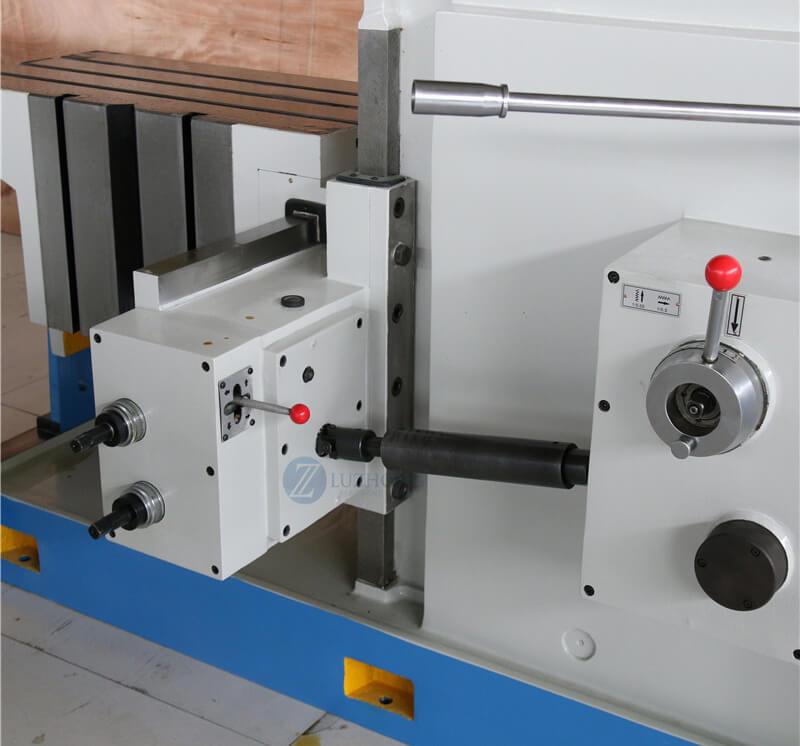

1 Optimize the principle of design, the machine is beautiful, easy to operate.

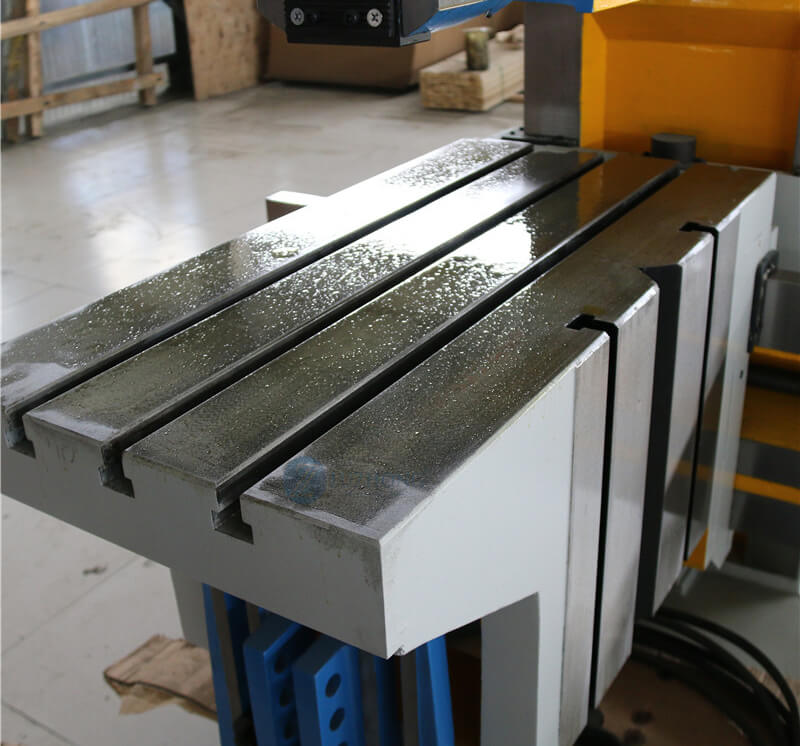

2 The vertical and horizontal guide rail is used for rectangular guide and the stability is better.

3 The use of advanced ultra - frequency quenching process, so that the machine's life longer.

4. It is suitable for cutting all kinds of small parts of the plane, T type groove and forming surface, can be used for single or mass production.

Product main technical specification:

Specification | Units | BC60100 |

Maximum shaping length | mm | 1000 |

Maximum moving distance of the working table(level) | mm | 800 |

Maximum distance from ram bottom to table surface | mm | 400 |

Maximum moving distance of the working table (vertical) | mm | 380 |

Table size (L*W) | mm | 1000×500 |

Maximum tool carrier travel | mm | 160 |

Tool carrier rotary angle | ° | ±60° |

Maximum size of tool planer(W*T) | mm | 30×45 |

Number of ram reciprocating per minute | 15、20、29、42、58、83 | |

Feeding range of horizontal travel(10steps) | mm | 0.3~3 |

Feeding range of vertical travel(10steps) | mm | 0.15~0.5 |

Speed of rapid travel horizontal table | mm | 3 |

Speed of rapid travel vertical table | mm/min | 0.5 |

T-slots width | mm | 22 |

Main motor power | kw | 7.50 |

Overall dimensions (L*W*H) | mm | 3640×1575×1780 |

N/G.W | kg | 4870/5150 |

Copyright © Shandong Luzhong Machine Tool Co.,Ltd. All Rights Reserved