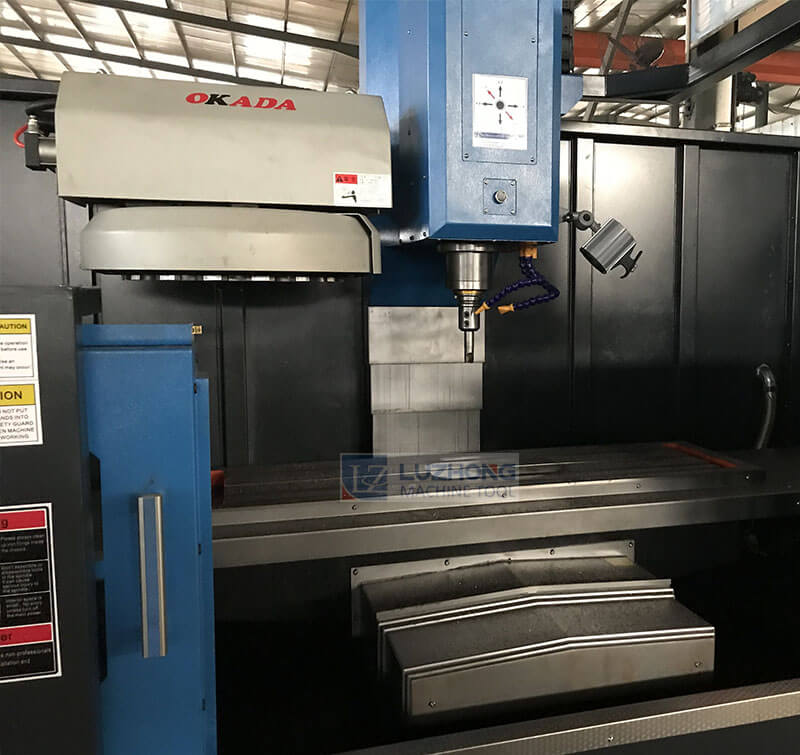

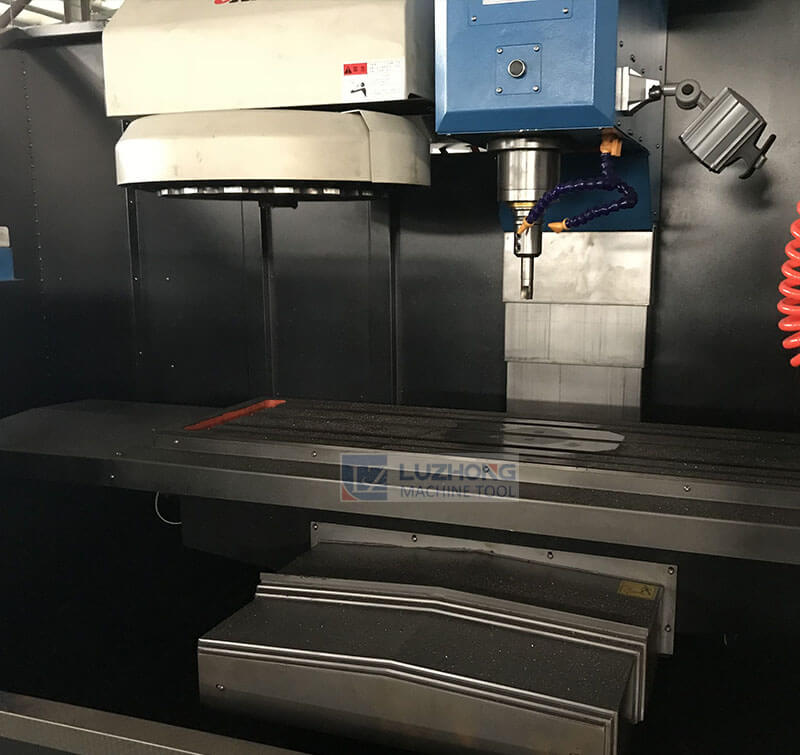

Features:

Taiwan spindle

Taiwan ball screw and locking nut

Sweden SKF bearing

Automatic lubrication system

Chip conveyor at optional

Application:

1. The main components such as base, column, workbench, middle slide and lifting slide are all cast from high-strength materials and treated by artificial aging to ensure the stability of long-term use of machine tools, providing stability for machine performance. Guarantee.

2, Choose high-speed, high-precision, high-rigidity spindle unit, strong carrying capacity, the highest speed of 8000rpm;

3. X axis travel of worktable is up to 1200 mm. Y and Z Axis guide rails are wide rectangular sliding guides, which are quenched and precision ground by super audio. The sliding guide surface is precisely scraped and coated with composite PTFE material, combined with automatic forced lubrication, reducing the friction resistance of the feed motion, reducing the low speed crawling and improving the precision life of the machine.

4. X, Y and Z axis feeds are all made of high-precision, high-strength ball screw and servo motor drive to ensure the positioning accuracy of the machine.

5. Guideway and ball screw use stainless steel protection device to ensure the cleaning of the lead screw and the guide rail to ensure the machine drive and running accuracy.

6. Z axis is equipped with a weight balancing device to ensure smooth and smooth movement of the spindle.

7. Electric lubrication device can force the lubrication of the vertical, horizontal and vertical lead screws and guide rails to reduce the wear of the machine tool and ensure the efficient operation of the machine tool. The cooling system can change the flow rate of the coolant by adjusting the nozzle to meet different processing. demand.

8. Machine tool operating system is suspended by the arm at the upper right of the machine tool. It conforms to the ergonomic principle. The operation box can be rotated by a certain angle, and the operation is convenient and reliable.

Product main technical specifications:

specifications | unit | VMC1050 |

Table size | mm | 1370x400 |

Table maximum load | kg | 400 |

X/Y/Z axis travel | mm | 1200x500x500 |

T slot number-width-space | 3-18-100 | |

Distance between spindle center and column surface | mm | 500 |

Distance between spindle end face and worktable surface | mm | 100-600 |

X rapid feed | m/min | 12 |

Y rapid feed | m/min | 12 |

Z rapid feed | m/min | 8 |

Max. spindle speed | r/min | 8000 |

Spindle taper | BT40 | |

Max. Tool diameter | Mm | 80/150 |

Spindle motor | kw | 5.5/7.5 |

X/Y/Z axis motor power | kw | 1.6/1.6/1.6 |

X/Y/Z axis motor torque | NM | 10 |

Coolant pump motor | W | 400 |

positioning accuracy | mm | 0.015/300 |

Repositioning accuracy | Mm | 0.008/300 |

X/Y/Z guide rail form | Box type | |

Tools type | 16 armless(24 arm) | |

Machine dimension | mm | 2600x2300x2350 |

Machine weight | t | 2.8t |

Copyright © Shandong Luzhong Machine Tool Co.,Ltd. All Rights Reserved